Who does what in the whisky creation process?

let’s begin

Ever wondered about the people behind the whisky you’re enjoying today?

As a whisky blogger and consultant, I’ve been lucky enough to visit my fair share of distilleries over the years and something that always strikes me as romantic is how little the process has changed over the years.

Sure, some distilleries have digitised their processes and mechanised whatever they can but some really do hold onto the history, heritage and ancient craft that is whisky creation.

On one particular distillery visit to Kininvie recently I asked the question as to why they never automated any of the stages of the process, their head of global travel retail, Ian Taylor responded with: “the product is linked to Dufftown, we could have automated the whole process but this is not our way… Dufftown made this, the people of Dufftown made this”.

In context, there are 189 people work on Glenfiddich’s distillery’s site, typically competitors employ around 4-25 and automate the process.

So who does what in the whisky creation process?

Maltman

The maltmen are responsible, in only a few remaining distilleries, for shovelling the corn, barley etc. to allow it to sugars to develop for 2-3 days. The grains then germinate on the malting floor to help produce the necessary enzymes required for about five days before being shovelled into a kiln of peat fire to stop germination.

Mashman

These guys are responsible for managing the process of turning malted barely into wort, and then wash. The mash tuns play a big part in the process – hence Mashman. In the Glenturret distillery the mash is still turned by hand.

Stillman

Formerly dodgers of the exciseman, stillmen are responsible for looking after the spirit safe in the distillery, ensuring the purity and quality of the spirit coming off the stills that will eventually mature into whisky. Stillmen are relatively senior in the distillery rankings, often having worked as a mashman and maltman previously.

Master Blender

Like the conductor of an orchestra, it is the Master Blender’s role to weave consistent flavours that represent the purity of the blend they are looking after through the years, often with different component parts that need to be balanced perfectly.

Master Distiller

The often heralded captain of the distillery, the master distiller is responsible for maintaining traditional principles of their respective distillery and applying them to new experiments in order to create new products for their loyal and prospective customers.

They also host a bunch of VIPs, brand people and are typically the face of the brand.

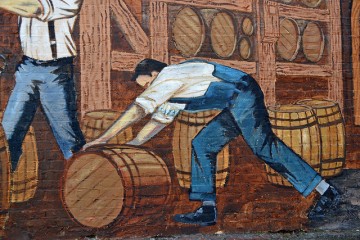

Cooper

Wow these guys have both a charmed and a very hard life; day in day out building or repairing the oak casks that whisky will ultimately age in. Penalised for imperfection but handsomely remunerated for their time, often being paid by the cask.

Ever enjoyed a whisky called Monkey Shoulder? Well, the name comes from the coopers’ role, it is the hunch that develops on the backs of distillery workers who spend most of their time hunched or in one position.

Warehouse Manager

Each day they take charge of all new cask fillings as well as quality assuring existing maturing stock and getting their hands dirty manoeuvring casks around the warehouse to where they need to be.

Bottlers

Most of the industry has mechanised their bottling operations but they still need quality controlling so a few people go through bottles at random and check them.

For super premium (think bottle costs of £250 and above) they typically hand seal and pack each whisky into its box to ensure none of the precious liquid is lost in transit or whilst being shipped to customers.

There you have it

I have left a few roles out as they get a bit further into the branding and sales side of things but as you can see there are a lot of people behind the incredible whiskies we all enjoy day to day.

Without them we would not be able to explore or talk about our journey through this fine spirit.

Let’s raise a glass to them and their efforts, slàinte.

Greg

2 thoughts on “Who does what in the whisky creation process?”