Distillery profile: Oban

let’s begin

The Oban distillery and whisky has long been on my bucket list of whisky experiences and I feel rather fortunate to have been given that opportunity recently after Linda of the Oban and Lorn Tourism Association (OLTA) spotted the frankly shocking admission on the GreatDrams Whisky Bucket List that I had not had a chance to try Oban 14 as yet and she boldly wanted to rectify the situation.

After driving through the glorious Scottish scenery (read more about Oban itself here), I was dropped off, grabbed a fresh crab sandwich and wandered around the bay to the Oban Distillery, just as 50,000 others do every year.

On arrival, and after obligatory selfie with the distillery sign, I walked inside to be enthusiastically greeted by Ronnie, Site Operations Manager for the Oban Distillery.

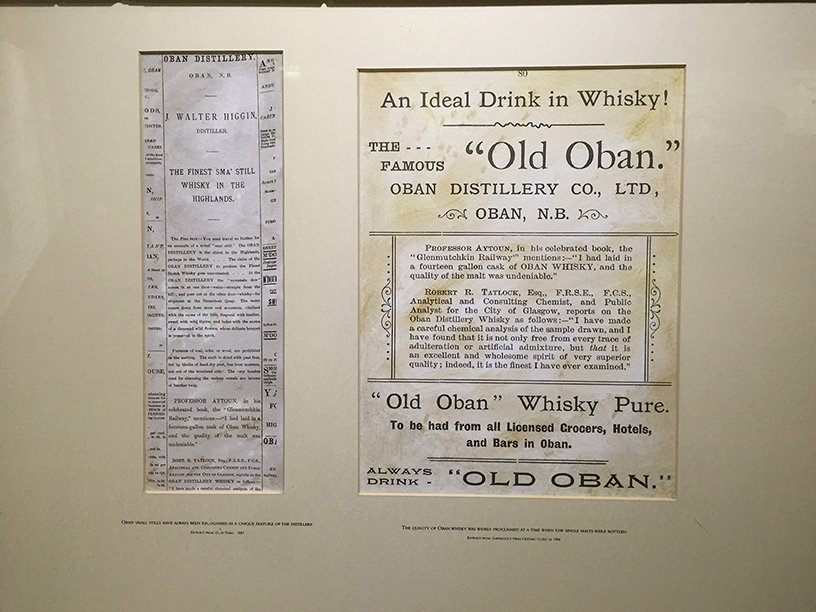

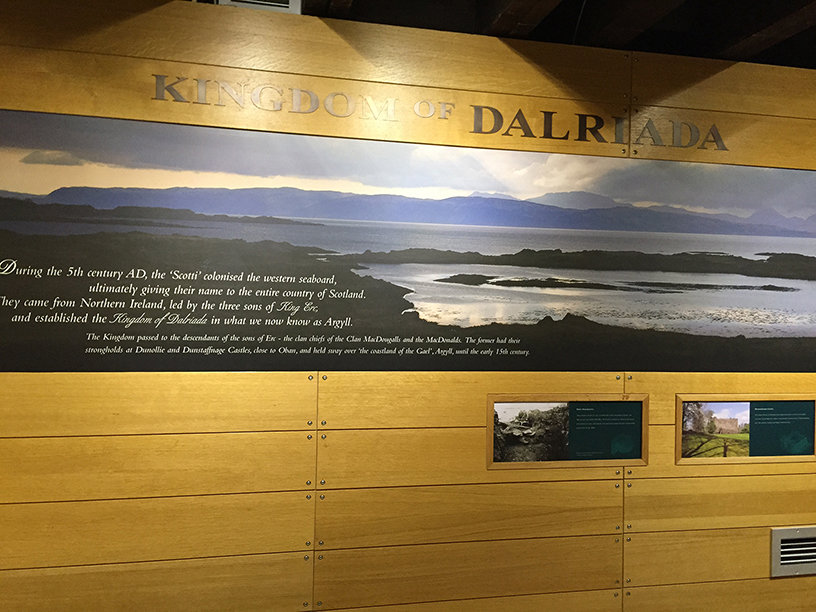

We wandered around the distillery, first going through the visitors centre, clocking the bar on the right for later, watching a scene-setting video as we went and admiring the packaging evolution and brand stories adorning the walls.

Ronnie talked me through various bits of the town’s history, how the distillery was here before the population meaning the town grew around the distillery which in fact started its life as a brewery, but the then founders made the right decision to convert it into a distillery a mere 12 months later.

Whilst The Macallan have their ‘curiously small’ stills, the Oban Distillery describe theirs as ‘distinctive small stills’, and they really are.

I was a tad shocked at how small the operation was in truth; just two pot stills and the ‘Seven Men of Oban’ who run the entire distillery, producing 800,000 litres of spirit a year.

Regular GreatDrams readers will know I love a good peaty whisky, but something I have not come across is a whisky peated to just 1ppm, but that’s how the Oban distillery rolls.

The distillery itself is very eco-conscious, like virtually all of them, and includes heat exchanges to regulate water temperatures for use along the process.

Ronnie proudly explained that “everything here is recycled, even sweet wrappers… the only think we cannot recycle is the cigarette ends but maybe one day eh?”

The distinctive small stills allows for a lot more copper contact, creating softer flavours that take away any potential for harsh notes in the end product.

They used to do all the bottling here too, until the year 2000, but that is done off site now with the spirit being taken away in tankers through the week.

Something really interesting about the Oban Distillery site is that they literally cannot expand.

They tried a few years ago but the effort was halted as during excavation of the cliffs at the back of the distillery found the remains of a cave-dwelling family from mesolithic period, dating back to around 10,000 to 5,000 BC.

But more interesting still is that the produce from the Oban Distillery is a designated “capped malt”, explains Ronnie, which essentially means that none of their spirit is allowed to be used in blends and is the only Diageo malt not to be blended into the Johnnie Walker range of premium blended scotch.

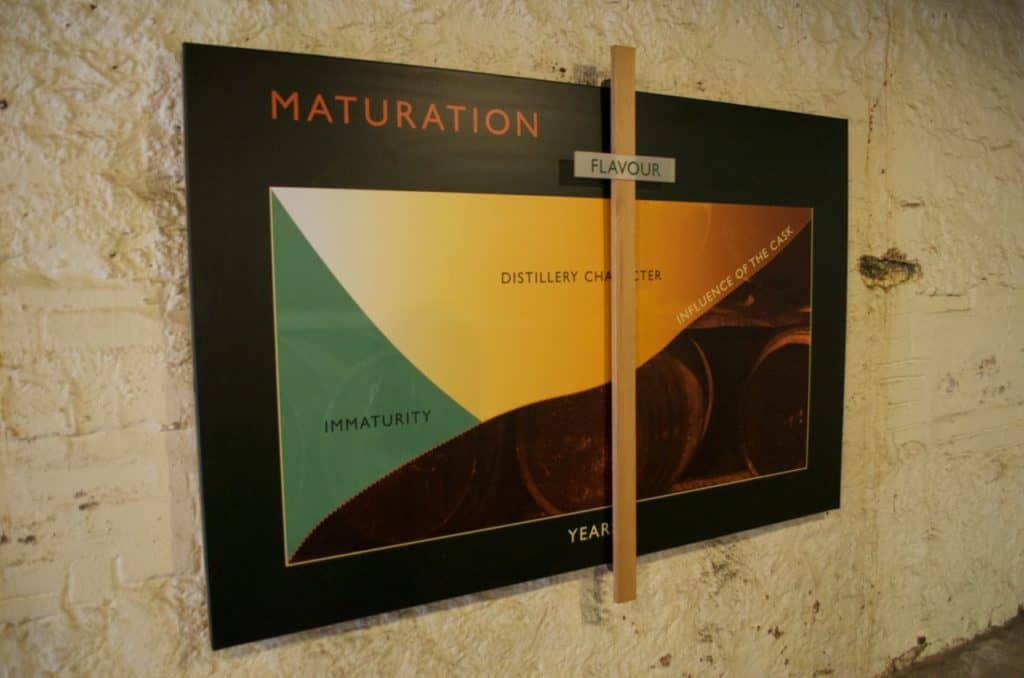

All Oban spirit is matured in refill bourbon casks that have previously housed North British grain spirit.

We then headed to the warehouse to sample a surprisingly fruity 12 Year Old Oban that definitely sits amongst the mellowest whiskies I’ve sampled in recent times.

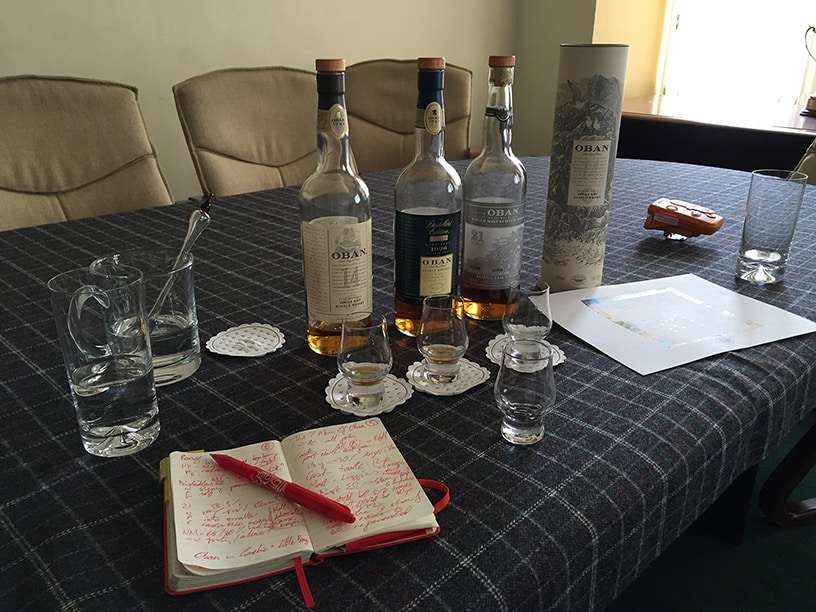

With that we headed to Ronnie’s office for a range tasting of what the Oban distillery has to offer… but I will be saving that for another time.

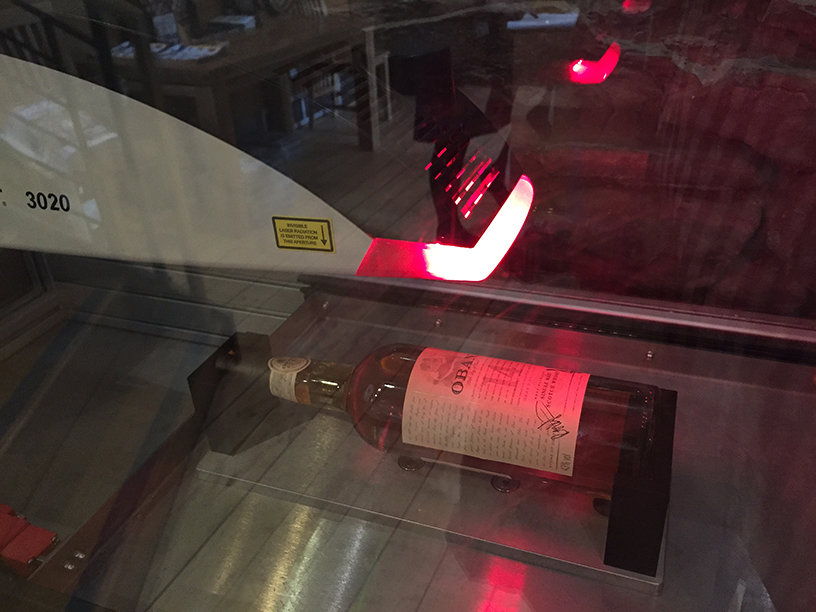

I was then deposited in the shop / bar for a couple more drams and left with an Oban 14 signed by some of the Seven and etched with the date I visited and the GreatDrams web address, what a great memento.

Huge thanks goes to Ronnie, Andy and the rest of the distillery team as well as Linda of course for being such great hosts and putting on a great show of what the Oban Distillery is all about.

Statto corner:

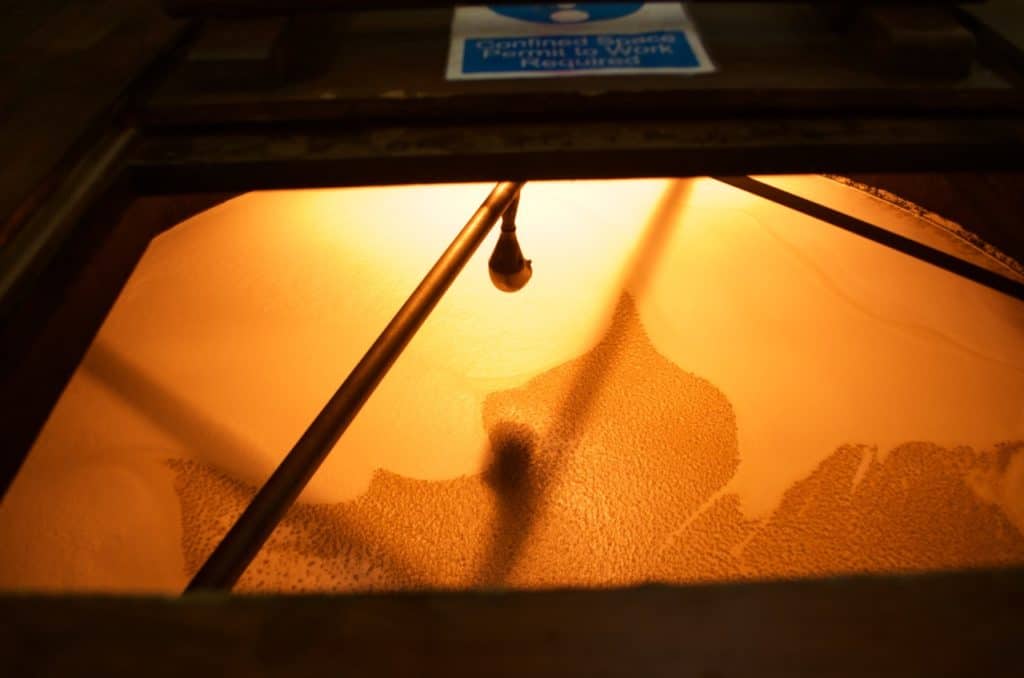

The mash is tired three times for ten hours each

7 tonnes of grist used during the mashing process

1st mash uses water at 63.5˚c

2nd mash uses water at 76˚c

3rd mash uses water at 83˚c to break the sugars down

Oban has four washbacks made of European larch wood

Time spent in washbacks = 110 hours to build flavours and develop that fruity aroma typical of Oban 14

Steam at 94 – 96˚c is used to clean the washbacks for 30 minutes in total

800,000 litres of spirit produced a year

4 thoughts on “Distillery profile: Oban”