Teeling Whiskey in Depth. Part Two: GreatDrams visits the Teeling Distillery, Dublin

let’s begin

A long time coming, GreatDrams finally managed to visit the Teeling whiskey distillery just a couple of weeks ago.

This is part two in a three part series looking at Teeling Whiskey in depth, you can Part one is available to read here.

With a mission to revive the Spirit of Dublin following the provenance of Irish whiskey in Dublin being lost, to a degree, once Irish Distillers consolidated family brands into Midleton distillery in the 1970s, The Teeling distillery and Irish whiskey at large has risen like the phoenix in their brand’s logo.

I was incredibly fortunate to have been given an afternoon of Jack Teeling’s time as he showed myself, my wife and my in-laws around the Teeling distillery and guided us through a number of their products.

One thing that strikes you is how much of an entrepreneur Jack is; he spotted an opportunity for a location, a brand and a whiskey that would invigorate the Irish whiskey market globally and went for it.

The location itself is around 200 metres from where his family once had a distillery in Dublin, back in the old days, founded by Walter Teeling so the ‘homecoming’ of sorts of the new site is definitely a source of pride for the Teeling brothers.

As soon as you walk in you are greeted by a wall made of cask staves adorned with a massive Teeling whiskey logo. A coffee shop is located to the right and an exhibition space for local artists and projects on the left that leads into the main distillery itself.

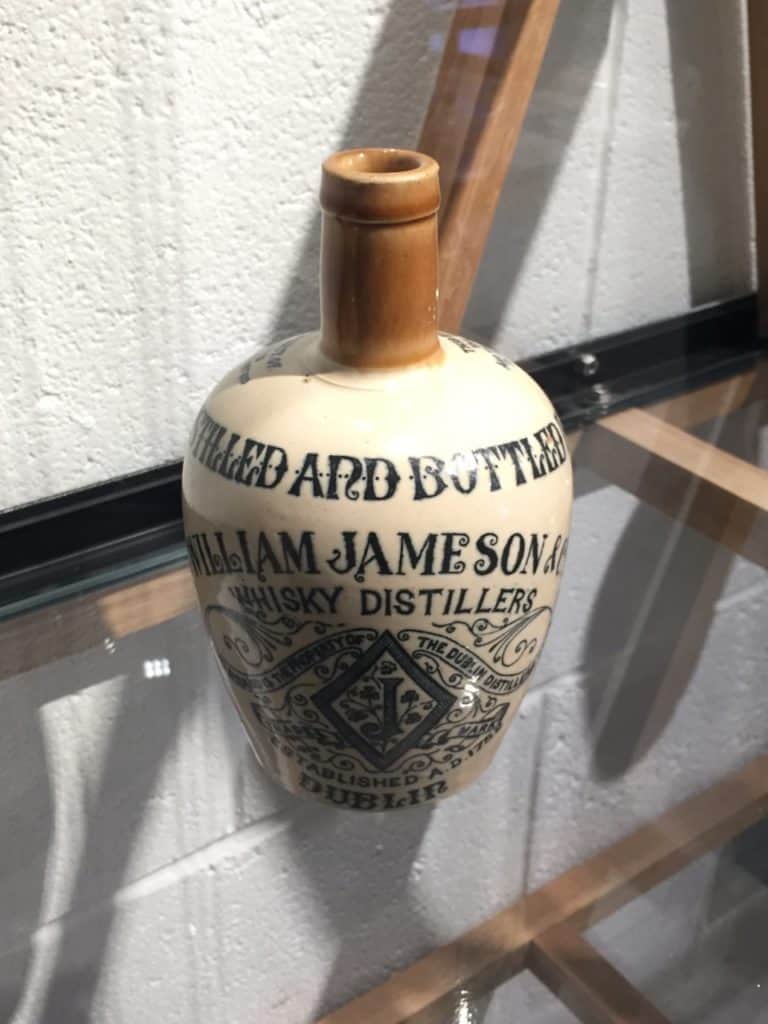

In this exhibition space there are artefacts detailing the history of Irish whiskey, from the old dark bottles and pottery transporting vessels to signage and adverts as well as a timeline on the wall.

This is not just a celebration of the Teeling distillery and its journey but a celebration of Irish distilling past, present and future.

The Teeling distillery itself has all production happening in one room and has been thoughtfully designed to make it as easy for visitors to walk around and understand as it is for staff to operate.

They have adapted brewing technology to beef up their process, a Lauter mash tun and a combination of steel and Douglas fir washbacks. At the time of visiting they had been experimenting to see if there are any flavour differences between the two once the fermentation hits the stills and new make is distilled.

Regular readers will know that I’m a sucker for beautiful stills, I have photos of the stills in virtually all distilleries I have visited and more often than not get a selfie with them too.

The stills at the Teeling distillery are gorgeous; made by Frilli in Italy, they have the shine of new copper but the rugged look of being the backbone of whiskey production for many decades to come. And they have been named after Jack’s three daughters; Alison, Natalie and Rebecca.

The distillery itself has an operating capacity of 1 million litres per annum but is currently operating at 350k litres per annum.

We bumped into with Alex, the Teeling Master Distiller who was more than happy to answer my questions on NPD and had a very approachable manner to him that showed pride and passion behind their various creations.

I asked him about how they test whiskies and go about NPD to which he gave a comprehensive answer.

They essentially categorise the stock then take 100ml of x amount of casks to blend together.

So, for example he might like the nose on the white burgundy but wants to add a bit of the port character to the palate so picks an appropriate cask to build the taste, then wants to add sherry to bring out a more elegant finish so again chooses a cask he thinks will work.

This concoction is then left in a glass or bottle for the weekend to see how it develops. If that works nicely the same blend will be made in a larger quantity, say six or seven bottles and left for longer to see the reaction and development of flavour and consistency.

They then send samples to industry folk and bloggers from time to time to get their feedback which they may or may not act on this before signing off the final blend for full production to fine the right amount of casks, i.e. 20 of component x, 25 of component y and 65 of components.

This whole process, he told us, takes around nine months start to finish.

Fascinating.

With the main Teeling distillery tour completed we walked through to the sampling room and bar area for an unforgettable whiskey tasting that will form part three of this Teeling Whiskey in Depth series.

1 thought on “Teeling Whiskey in Depth. Part Two: GreatDrams visits the Teeling Distillery, Dublin”